Central air conditioning water system in operation process will produce large scale, sludge, rust corrosion products and algae biological Nien mud, the dirt deposited in the change of the surface of the heat exchanger tube, seriously affecting the central air conditioning refrigeration effect and the service life. Therefore, we need to in central air conditioning cooling water system and chilled water system regularly cast plus a variety of water treatment chemicals, such as slow corrosion and scale inhibition agent, dispersing agent, bactericide, water fouling ion stability in water, prevent scaling, microorganisms, algae, generation and control of corrosion and protection of the role of central air conditioning unit. This method is the most widely used method for industrial circulating water treatment and central air conditioning water treatment. The practice proves that it is an effective and economical method.

Central air conditioning water treatment to improve the cooling effect of the central air conditioning, energy conservation, suppression of equipment corrosion, to extend the service life of the unit is of practical significance and practical value.

Air conditioning closed water system cleaning

.jpg)

Cleaning and cooling tower

Take water sample

The dosing

On site detection of water quality

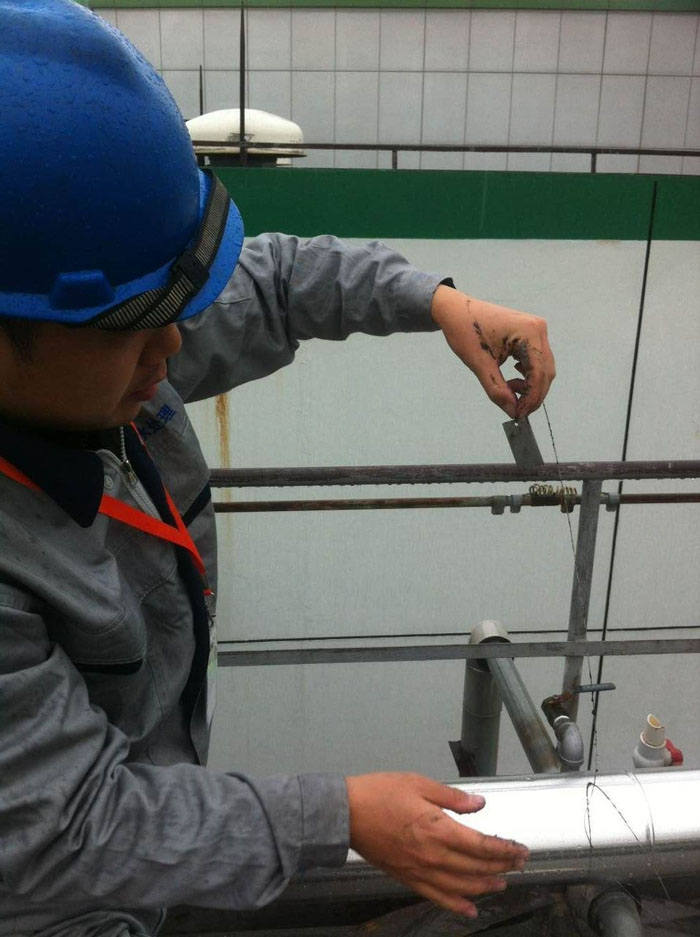

Spot check coupon

Automatic controlled dosing equipment

The necessity and purpose of water treatment of central air conditioning

1、Due to the presence of calcium and magnesium in water, salts, air conditioning water system inevitably will bear all kinds of scales, because the scale of the thermal conductivity is carbon steel of an lang= "EN-US" >1.11%, grease, algae and slime thermal conductivity is only carbon steel of an lang= EN-US > 0.23%, when the air conditioning water system node from dirt, the unit heat transfer performance deterioration, exhaust pressure increases, the cooling efficiency decreased, resulting in energy waste, operation and maintenance costs increase, serious scaling will enable host high voltage disconnect protection, directly affects the unit normal operation.

2、Scale to make concentration of dissolved oxygen in water and fouling metal surface oxygen concentration produced a concentration difference, resulting in the formation of oxygen concentration difference cell, the scale of metal corrosion. At the same time, mud will also be the metal corrosion, corrosion results will greatly increase the system's operation and maintenance costs, shorten the service life of the equipment, can make the host in advance.

3、According to the air conditioning system scale and oxygen corrosion failure, must be regular cleaning and daily water treatment. Safe and effective chemical cleaning can achieve safe and normal operation, which can significantly improve the cooling capacity and heating efficiency. The operating cost, electricity, oil and gas consumption of the system is greatly decreased after the cleaning. Corrosion and scale inhibition, corrosion after the pre membrane protect the host and network from corrosion, no longer scale, extend the service life of the unit.

The most commonly used scheme is the chemical method, by adding water quality stabilizer, such as corrosion and scale inhibitor, dispersing agent, bactericide, water fouling ion stability in water. The principle is by chelation, complexation and sorption dispersion, the calcium and magnesium ions stably by chelate complex is dissolved in water, and the iron oxide and silica gel has good dispersion effect. Due to the formation of the inhibitor on the metal surface is not soluble in water or difficult to dissolve in water protective film, due to the inhibition of metal ions of the hydration reaction or dissolved oxygen reaction, and the inhibition of corrosion reaction. Specific chemical corrosion and scale inhibition below introduced. This method is the central air-conditioning water treatment using a kind of the most common methods and also in industrial water treatment is widely used, technology is the most mature method. Practice has proved that the is an effective and economic method.

Effect of central air conditioning water treatment

(1)Obviously improve the cooling effect, reduce the accident: central air conditioning water treatment can kill algae, remove the sludge, make the line flow, clear water. And improve the central air conditioner condenser, evaporator heat exchange efficiency, so as to avoid the operation of the high voltage, overpressure shutdown phenomenon and improve the chilled water flow, improve the cooling effect, for heat exchanger and temperature difference 1-2 DEG C, chilled water temperature decreased by 2 to 4 DEG C, cooling effect provided 10-30% higher, the safety and efficient operation of the system.

(2)Greatly save energy, reduce costs: due to the presence of sediment will greatly reduce the efficiency of heat exchangers, electricity consumption increased. A cold water chiller, the heat exchange efficiency of the condenser is reduced, resulting in a significant increase in the power consumption of the compressor, and the cooling coefficient is greatly reduced. As can be seen from the pressure enthalpy chart, the heat exchange efficiency of the condenser can be reduced, resulting in a significant increase in the power consumption of the compressor, and the cooling coefficient is greatly reduced. According to calculation shows that, condensing temperature between 25 - 40 DEG C, due to the condensation pressure increased, the condensing temperature corresponding to each 1 degree Celsius, then consumption of electricity increased by about 3.2.

26.88%=91445; elevated 270KW/ cases: a cooling capacity of 100 million kcal of water-cooled chiller, equipment rated power consumption for hours due to the condenser fouling the unit condensing pressure from 17 kg increased to 21 kg, condensing temperature corresponding from 48.3 DEG C to 56.7 DEG C, condensing temperature increased 8.4 DEG C unit electricity consumption increased by 8.4 DEG C x 3.2% =26.88% unit refrigeration quarter run for 6 months to run every day 10 hours a total of 1800 hours, the unit average load of 70%, a refrigeration quarter to power: 270 x 70 x 18 x to every degree of electricity 0.7 yuan, the annual waste of electricity is RMB 64011.5.

Central air-conditioning water treatment in the removal of scale, prevent the formation of scale, improve the efficiency of heat exchange at the same time, but also reduce the consumption of electricity or fuel. Energy saving 10-30% above, the central air conditioning water treatment can also reduce the system discharge, improve the utilization rate of circulating water. So as to reduce the production cost.

(3)Protection equipment, extend the service life: (extend the service life of pipelines and equipment, that is, the effect of water treatment is to make the pipeline and equipment to achieve the design life): central air-conditioning water treatment can rust, anti fouling. To avoid equipment corrosion, damage, especially after the prevention of treatment, so that the service life of the equipment is doubled. Input inhibitor, can make the equipment corrosion rate decreased by 90%, eliminate the cooling water system of "yellow water" phenomenon.

(4)Substantial savings in maintenance costs: without water treatment of central air conditioning, there will be equipment pipeline blockage, scaling, corrosion, overpressure shutdown or even failure. Such as: operating system for corrosion leakage, resulting in solution contamination, you need to replace the thermal device and solution, the central air conditioning maintenance fees generally require 20-50 million. Central air conditioning water treatment, you can reduce the maintenance costs, and can extend the service life of the equipment, to create a better economic benefits for the user.

(5)Environmental emissions, wholesome: central air-conditioning cleaning and corrosion and scale inhibition, sterilization and algae in the water, after treatment, the water is clear, can also kill the air conditioning water Legionella great harm to human body, central air conditioning for the cooling and heating clean, safe, is conducive to the health of users.

Central air conditioning water treatment program

一.Water quality analysis

Central air conditioning circulating water detection project: the total number of pH, conductivity, total hardness, total alkalinity, turbidity, total iron, total copper, residual chlorine, bacteria.

二.Water quality treatment process

Circulating water treatment of the task is to remove the old and the new system, equipment of water rust, slime, biological bacteria algae and in clean the inner wall of the pre membrane layer of thin and dense protective film (passive film) finally according to the variation of the daily water system, through water quality analysis adding compound corrosion inhibitor, scale inhibitor, dispersion bactericide and algicide, delay the corrosion system, prevent rust fouling, prevent slime sedimentation and breeding of bacteria and algae.

1. Pretreatment

Pretreatment includes cleaning and pre membrane. Cleaning is divided into physical cleaning and chemical cleaning, physical cleaning is to use manual cleaning and water washing, in order to remove the residual sediment, construction waste, etc.. Chemical cleaning is the chemical cleaning agent to remove oil pipeline equipment, scaling, slime, rust, bacteria, algae and other impurities, achieve the purpose of cleaning the surfaces of metal, to lay a good foundation for pre film to reduce the thermal resistance.

Cleaning agent for high molecular organic compounds, the equipment and piping without any damage. Its mechanism is penetration, diffusion and chelation, energy efficiency is the removal of dirt rust.

The compound formula of the pre film agent system has the synergistic effect, and can quickly form a chemical protective film on the cleaned metal surface, so that the pipeline equipment has good corrosion inhibition and scale inhibition effect, and prolongs the service life of the equipment.

2.Daily maintenance

After the pretreatment, the system runs normally, and enters the daily processing stage. According to the water stability test of our company, the preliminary formulation of the reagent and the initial concentration, corrosion inhibition, scale inhibition, sterilization treatment. According to the analysis of the water quality and quantity of the water and the water treatment effect, the formula can be adjusted at any time, so as to ensure the optimal combination of the reagent and the process to achieve the best effect of water treatment.

三.Water treatment cleaning process

1.The cooling tower and the expansion water tank in the water system are added with stripping agent, sterilization and algae killing agent, and adding a certain amount of dispersant, through the water cycle running 24-48 hours, to carry out sterilization and algae removal of dirt, finally sewage.

2.In the water system adding cleaning agent, removing system dirt and rust, through the water cycle for 12-24 hours and sewage to turbidity less than 15ppm. The Y type filter of the filter is disassembled for cleaning.

3.In the water system to join the pretreatment of the surface passivation treatment, running time in about 24 hours, pH value between 6-6.5, sewage to the turbidity is less than 5PPM.

4.Daily maintenance, reagent concentration on the basis of the specific water quality, by analysis of the supervisory decision dosage, to maintain and repair system in the metal surface to form a protective film, to prevent and disperse into dirt ion scaling, achieve anticorrosive, anti fouling and to control the growth of microorganisms.