The demand of sewage treatment is accompanied by the birth of the city. Urban sewage treatment technology, after hundreds of years of change, from the initial stage of development to the current level of three treatment, from simple disinfection and precipitation to the removal of organic matter, nitrogen and phosphorus removal to the depth of treatment. Among them, the advent of the activated sludge process is of great significance, and this year is the 100 anniversary of the birth of the activated sludge process. Urban sewage treatment technology in the future will be how to develop? In this regard, it is better to let us look at those years of urban sewage treatment through the road.

First stage treatment

Urban sewage treatment history can be traced back to the ancient Roman times, the period of high environmental capacity and the self purification capacity of water bodies can also meet the water demand of human, people only need to consider the drainage problems can be. Then, the urbanization process is accelerated, the spread of infectious diseases caused by the spread of domestic sewage, for health considerations, human beings began to deal with the discharge of sewage treatment. Early treatment methods using lime, alum and other precipitation or bleaching powder for disinfection. In the late Ming Dynasty, China has already had the sewage purification equipment. However, due to the demand is not strong at that time, China's domestic sewage is still mainly agricultural irrigation. In 1762, the British began to use lime and metal salts, such as urban sewage treatment.

The secondary processing phase

Organic matter removal process

Biological membrane method

In the middle of the eighteenth Century, the European Industrial Revolution began, and the organic matter in urban domestic sewage became the focus of the removal. In 1881, the French scientists invented the first bioreactor, is also the first anaerobic treatment pool — Moris pool was born, opened the prelude to biological treatment of sewage. In 1893, the first biological filter in the UK Wales put into use, and quickly in Europe and North America and other countries to promote. Technology development, and promote the generation of the standard. In 1912, the Royal Council of sewage treatment proposed to BOD5 to evaluate the extent of water pollution.

Activated sludge process

In 1914, Arden and Lokett in British Society of chemical industry and Trade: the a paper on the activated sludge process, and in the same year in Manchester, England pioneered the world first seat activated sludge wastewater treatment pilot plant. Two years later, the United States formally established the first activated sludge process sewage treatment plant. The birth of the activated sludge process, laid the foundation of the city sewage treatment technology in the next 100 years.

At the beginning of the birth of the activated sludge method, uses is the charge - discharge process, because when automatic control technology and equipment is relatively backward, cause because of the complicated operation, easy to plug, and the biological filter compared with no obvious advantage. After continuous inflow of plug flow activated sludge process (CAS) (Figure 1) after soon will replace the, but due to the plug flow reactor sludge consumption rate of oxygen along the length of the pool is changing, rate of oxygen supply to its cooperation, activated sludge method facing the problem of local oxygen deficiency. In 1936, the gradual aeration activated sludge process (TAAs) and the stage aeration method (SFAS) proposed in 1942, which improved the oxygen supply balance from the aeration mode and the water inlet mode. In 1950, Mckinney put forward a completely mixed activated sludge process. This method can adapt to the change of the concentration of the substrate in the aeration tank by changing the living way of the activated sludge microbial population, which can effectively solve the problem of sludge expansion.

With the extensive application of the actual production and technical innovation and improvement, in twentieth Century 40-60 years, activated sludge process has gradually replaced the biofilm process, becoming the mainstream of wastewater treatment process.

In 1921, activated sludge process was spread to China, China Construction of the first sewage treatment plant — Shanghai North District sewage treatment plant. 1926 and 1927, respectively, the construction of the eastern and Western Shanghai sewage treatment plant, at the time of the 3 water treatment of a total of 35 thousand and 500 tons.

Nitrogen and phosphorus removal process

In 1950s, the problem of eutrophication is highlighted, and the removal of nitrogen and phosphorus is the main demand of wastewater treatment. Therefore, a series of nitrogen and phosphorus removal processes were derived on the basis of activated sludge process.

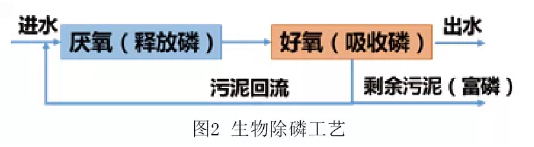

Phosphorus removal process

In the early 50s, the phosphor was found and used for phosphorus removal. (Figure 2)

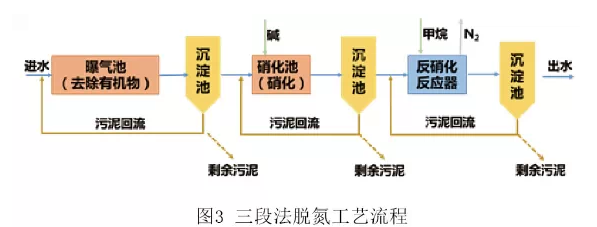

Nitrogen removal process

In 1969, the United States of the United States by the use of three Barth in addition to nitrogen (Figure 3), the first paragraph is the aerobic section, the main removal of organic matter, second sections of the addition of alkali and nitrification, the third section is anaerobic denitrification, nitrogen removal.

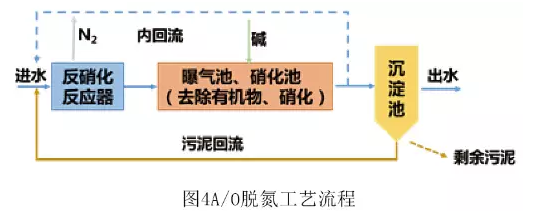

In 1973, Barnard on the basis of the original process, the anoxic aerobic reactor completely separated, sludge returned to the anoxic reactor, and add the internal reflux device, shorten the process, is now often said that the anoxic aerobic (A / O) process (Figure 4).

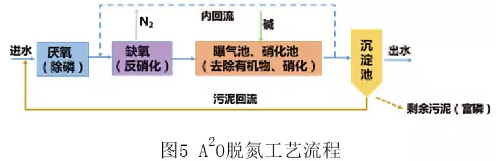

A2O process

In 70s, the United States experts on the basis of the A/O process, coupled with the phosphorus has become the A2O process (Figure 5). In 1986, China set up factories in Guangzhou Datansha sewage treatment plant, the use is A2O process, was designed to deal with water for 15 million tons, at that time in the world the biggest using A2O process of sewage treatment plant.

氧化沟工艺

A2O process is the biological treatment of aerobic and anaerobic section of the space partition, and oxidation ditch is closed to the trench structure, combined plug flow and completely mixed activated sludge process, aeration, sedimentation and sludge stabilization in one. The mixed liquid of sewage and activated sludge is constantly circulating, and the system can form aerobic and anoxic zones, which can realize biological nitrogen and phosphorus removal (Fig. 6). The oxidation ditch is used in the daytime, and is used as a sedimentation tank at night. Compared with activated sludge process, it has the advantages of simple processing technology, simple structure, long sludge age, less residual sludge, easy dehydration, stable treatment effect and so on.

In 1953, Public Health Engineering Research Institute of Dutch PASVEER research proposed the oxidation ditch process, also known as & ldquo; Paz de Gou & rdquo;. In 1954, in Holland, (Voorshoten) built the first oxidation ditch sewage treatment plant, when the service population of only 360 people. In 60s, this technology in Europe, North America and South Africa and other countries have been rapid promotion and application. According to statistics, by 1977, in Western Europe has more than more than 2 thousand blocks of the trench type oxidation ditch put into operation.

In 1967, Holland DHV company developed a carrousel oxidation ditch (Carroussel). The oxidation ditch system is composed of a plurality of channels and a plurality of channels. Carrousel oxidation ditch of development has gone through three stages: common Carrousel oxidation ditch, Carrousel 2000 oxidation ditch and carrousel 3000 oxidation ditch.

In 1970, the United States of America's Envirex on the production of the Obel (Orbal) oxidation ditch. It consists of three concentric circular or elliptical channels, each channel are communicated, inlet is first introduced into the channel, in which continuous cycle at the same time, turn into a channel, equivalent to a series of completely mixed reactor connected in series, the last from the center of the channel discharge.

Alternate work type oxidation ditch is developed by Danish Kruger (Kruger) company, the process cost low, easy to maintain, there are usually alternate Shuanggou and tricolpate alternating (T-type oxidation ditch) oxidation ditch system and semi alternating oxidation ditch.

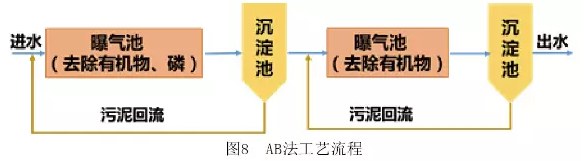

Two stage method

Two early law only two groups of an activated sludge process structures in series, the same one stage and two stage aeration tank volume, and more with the construction, most of the organic matter in the first paragraph is the adsorption and degradation, the sludge load is very low, the effluent water quality to superior to that of the same volume of an aeration tank single-stage activated sludge process (Figure 7). However, due to the reduction of the volume of the first section of the aeration tank, the sludge load is doubled, which is in the stage of sludge expansion, and the operation management is difficult.

In the middle of 1970s, Professor Bohnke AB of Germany developed the Botho process (Figure 8). The process on the basis of the traditional two-stage method to further improve the first segment is a segment of the sludge load, run in high load, short sludge age, and section B and conventional activated sludge process similar, the load is low, the longer sludge age, a due to short SRT, mud weight high on phosphorus removal effect is very good, after a period of removal of the large amounts of organic matter after B section of the volume can be greatly reduced and the low load operation mode can be to improve the water quality of effluent. However, due to the removal of a large number of organic matter in the A section of the B source of carbon loss, so in the treatment of low concentration of urban sewage, the advantages of the process is not obvious.

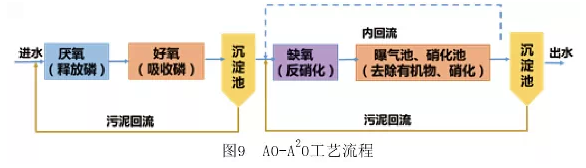

Subsequently, in order to solve the problem of long sludge age, when the removal of nitrogen and phosphorus removal, phosphorus removal microbes need short sludge age, the AO-A2O process was developed (Figure 9). The process consists of two relatively independent of the nitrogen and phosphorus removal process, short in the first half of the Niling, mainly for phosphorus removal, the sludge age is long, low load for nitrogen removal.

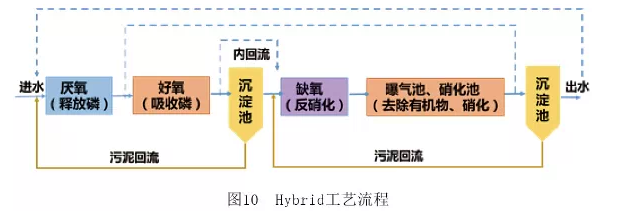

In the AO-A2O process on the basis of the Austrian R & D out of the hybrid process (Figure 10), the process between the two sections has three internal reflux device, can provide for the first section of aeration tank nitrate nitrogen, nitrification bacteria and for the second section of aeration tank to provide carbon source. The first stage is mainly to remove organic matter and phosphorus, the second part is nitrification function, and by the first part of the aeration tank reflux mixture for denitrification.

SBR process

Sequencing batch reactor activated sludge process (SBR) is a method to segment the anaerobic and aerobic segments in time. In early 1970s by the United States Irvine company development. It has only one basic unit in the process, the function of regulating pond, aeration tank and two settling tank in a pool, the water quality and water quantity regulation, the organic matter and the solid liquid separation and so on. The operation process of the classic SBR reactor is: water → aeration &rarr precipitation; → &rarr water decanter; standby (Figu"