Manual of activated carbon

一、Principle of active carbon filter

The adsorption capacity of activated carbon has a certain relationship with the level of water temperature, water quality and so on. The higher the temperature, the greater the adsorption capacity of activated carbon; if the water temperature as high as 30 degrees Celsius, the adsorption capacity to reach the limit, and there is a gradual reduction of the possible. When the water quality is acidic, the adsorption ability of activated carbon to anion material is relatively weak. When the water quality is alkaline, the adsorption ability of activated carbon to the cation material is weakened. Therefore, the water quality of the PH is not stable, it will also affect the adsorption capacity of activated carbon.

Activated carbon adsorption principle is: in the particle surface to form a layer of surface concentration of equilibrium, and then the organic material impurities adsorbed to the active carbon particles, the use of the initial adsorption effect is very high. But for a long time, the adsorption capacity of activated carbon would be decreased in varying degrees, and the adsorption effect also decreased. If the water in the aquarium water turbidity, high content of organic matter in water, activated carbon will soon lose the filter function. Therefore, activated carbon should be regularly cleaned or replaced.

The size of the activated carbon particles also had an effect on the adsorption capacity. Generally speaking, the smaller the particle size, the greater the filtration area. Therefore, the total area of powdered activated carbon is the largest, the best adsorption effect, but the powder like activated carbon is easy to flow into the aquarium, it is difficult to control, rarely used. Granular activated carbon is not easy to flow, such as organic impurities in the active carbon filter layer is not easy to block, and its adsorption capacity, easy to carry and replace.

The adsorption capacity of activated carbon is proportional to the time of contact with water, the longer the contact time, the better the water quality after filtration. Note: filtered water should slowly flow out of the filter layer. The new activated carbon should be washed before the first use clean, otherwise there is ink black water outflow. Activated carbon filter is loaded before, should be in the bottom and the top of the overlay 2 to 3 cm thick sponge, role is to prevent algae and other large impurity particles penetrate, activated carbon used for 2 to 3 months, if the decline in the filtering effect should be the new exchange, activated carbon, sponge layer to regular replacement.

二、The main properties of granular activated carbon

Application of granular activated carbon, especially a large number of applications, the most effect and cost of activated carbon is the main properties: adsorption amount; pressure drop or bed expansion; wear resistance; size, moisture, ash, pH value and soluble.

Application of a large number of granular activated carbon are packed in the column equipment, it is necessary to stress the pressure drop (pressure head loss) or bed expansion, is the necessary factor in the design of carbon column. The pressure drop is determined by the particle size and size distribution. Particle size, shape, and size distribution of the bed expansion and particle density are determined.

A lot of granular activated carbon, and often add water to pump and transport with dehydration, so we should pay attention to the loss of activated carbon, stress the wear resistance of activated carbon.

三、Evaluation of adsorption capacity of activated carbon

Adsorption of liquid phase adsorption and gas phase adsorption two kinds of liquid phase adsorption capacity is often evaluated by adsorption isotherm, gas phase adsorption capacity in order to evaluate the solvent vapor adsorption capacity. Adsorption isotherms said the relationship between partial pressure or concentration and the adsorption amount of system adsorption material of adsorption under a certain temperature. If the temperature is kept constant, measured equilibrium adsorption capacity and the relationship between pressure or concentration. With residual concentration for the horizontal axis, with single active carbon adsorption quality for longitudinal axis can be draw curve. When the partial pressure or concentration unchanged, can measure the balance the relationship between quantity and temperature of adsorption, draw the relation curve, namely, adsorption isobar. Adsorption isotherm is the most important and commonly used in the process of adsorption of a small amount of components in an industrial plant. Solvent vapor adsorption said vapor adsorption properties available granular activated carbon tetrachloride adsorption rate determination as an example, under specified test conditions, namely, to stipulate the carbon layer height, gas than speed, adsorption temperature, measured pipe cross-sectional area, carbon tetrachloride vapor concentration conditions, to contain certain carbon tetrachloride vapor concentration of the mixed air flow through active carbon, when the adsorption reached saturation, the percentage of carbon tetrachloride adsorption by activated carbon sample quality and the quality of the sample as carbon tetrachloride adsorption rate. In the application of activated carbon for adsorption capacity, it is best to use the actual intended use of activated carbon, the conditions of operation, the specific treatment for evaluation and testing. The adsorption capacity of activated carbon, namely unit activated carbon adsorbed amount of adsorbate, industry also has said for the activity of activated carbon, activity two representations: static activity -- and that is commonly referred to as the adsorption agent to achieve the equilibrium adsorption capacity. Moving activity - that is fluid mixture through a bed of activated carbon, in which adsorbate adsorbate. After some time of operation, the bed of activated carbon is a flow of the fluid began to appear to contain some of the adsorbate, indicating a bed of activated carbon loss of sorption capacity, amount of this activated carbon adsorbed on the adsorbate, known for the activity of activated carbon. Is the design of a large number of regular and important data required for the adsorption system.

The standard practical method for the determination of the adsorption capacity of activated carbon by the method of equal temperature line method can be used to determine the absorption capacity of the original and RE activated and powdered activated carbon.

四、Relationship between specific surface area and adsorption capacity of activated carbon

Generally speaking, the greater the specific surface area (BET) of activated carbon, the greater the adsorption capacity, but sometimes it is not necessarily. BET is the application of the measured parameters the total surface area of activated carbon adsorption method for nitrogen or butane. Normally BET is larger, the greater adsorption capacity. But in the practical application of this concept has limitations, because of the difference between activated carbon pores of macroporous, mesoporous and microporous, sometimes are only part of the hole for in a class size of adsorbate. In the liquid phase, the adsorption value of the organic compounds increases with the increase of the molecular weight (molecular size). Until the molecule is so large that it can not be in the hole. The most ideal activated carbon has a large number of pores which are slightly larger than the adsorbed molecules. The adsorption is small and the absorption is not large, so the surface area of unit volume is reduced. In the application of gas phase, small molecules are adsorbed into the pores. The concept of the total surface area is used. As for the adsorption of activated carbon on metal complexes, involving the formation of chemical bonds, it is not the bigger the better BET.

五、The application of activated carbon in liquid phase adsorption

Activated carbon in the liquid phase is mainly used for decolorization and purification, and sometimes for the collection and recycling or separation.

Liquid with activated carbon for decoloration refining, in addition to the decolorization adsorption (i.e. remove in the wavelength of visible light with light absorbing material) and outside the wavelength of visible light with light absorbing material is removed, remove the color of the forequarters material, removal of odor substance or adjust the flavor, remove the odor of the forequarters substances, removal of turbidity and may lead to a turbid material, removal of foaming material, remove the hinder the crystallization of the material, removal of colloidal substances, removal of protective colloid matter, removal of harmful substances in physiological, and removed to promote the product deterioration of materials, with many refinement of.

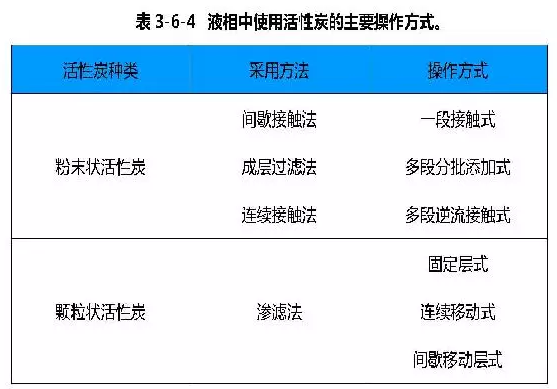

Liquid diffusion rate is much smaller than that of gas, so that the particle size of powdered activated carbon is often used in order to obtain the adsorption effect in a short period of time. However, in the case of a large amount of treatment, the use cases of granular activity increased continuously. Because it is easy to operate, easy to regenerate. Table 3-6-4 in the liquid phase of the use of activated carbon is the main mode of operation.

六、Application of activated carbon in the purification of gases

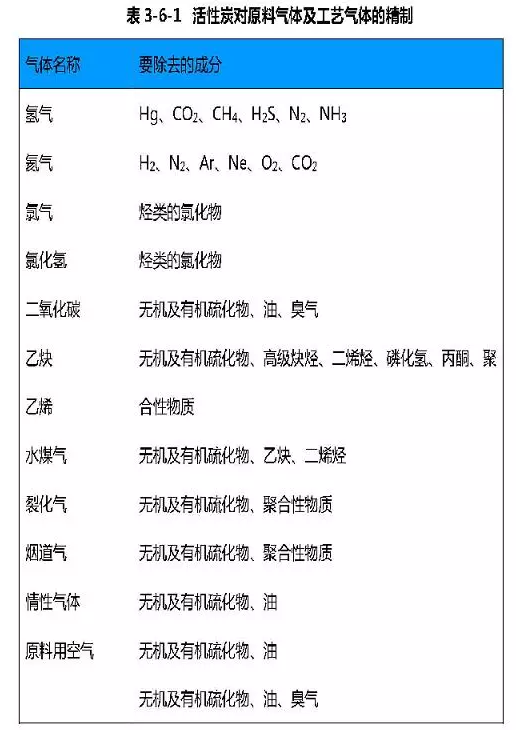

Refined industrial raw gas or process gas activated carbon for refining a variety of industrial raw gas or process gas, in order to remove all kinds of impurities contained in them, improve the purity and use value. Table 3-6-1 shows some of the name of the gas to be refined with activated carbon and impurities to be removed.

By the table 3-6-1 visible, using activated carbon purification gas is small molecules, low boiling point gas in a small amount of large molecules, high boiling point of the gas removed.

七、Application of activated carbon in liquid phase adsorption

Water treatment is widely used in the treatment of activated carbon, the largest potential sector. The quality of drinking water is directly related to human health; drainage and wastewater treatment or not have a significant impact on the earth's water environment. More than 50% of the amount of activated carbon in the developed countries is related to water treatment.

(1)Sheung Shui (water): Sheung Shui with activated carbon treatment is to improve the quality of water, remove the stink, stink, humus, oil, pesticides, detergents and other harmful substances.

(2)Treatment of water: activated carbon in the treatment of a variety of production water to obtain a wide range of applications. Such as in the brewing industry, the soft drink industry and ice making industry, using activated carbon to remove groundwater in color, odor, colloid substances, detergent, pesticide and other organic matter, or removal of water free chlorine, odor and other; electric power, chemical and other industrial sectors with activated carbon processing boiler water and boiler return water deoiling; pharmaceutical industry with activated carbon to remove water pyrogen; electronic industrial use activated carbon was prepared from ultra pure water; shipping industry using activated carbon drinking water; aquarium with activated carbon removal of chlorine in tap water.

In addition, activated carbon is also used to protect the ion exchange resin, purification plant recycling water, etc..

(3)Treatment of wastewater: a variety of production process of waste water discharged, containing different impurities, but relatively simple, easy to handle. Therefore, it should be treated after discharge or recycling.

(4)Treatment of sewage (sewage): sewage is a variety of waste water sinks into the integration of the sewage, the composition is very complex. In the treatment, the coagulation sedimentation method (physical method), the active carbon mud method (biological method) and the activated carbon adsorption method are used to improve the treatment effect and reduce the cost of treatment. Activated carbon treatment is usually used in conjunction with biological methods, or at the end as a final treatment. After treatment, you can remove the color, pesticides, detergents, odor, as well as BOD, COD, TOC and other impurities, as industrial and agricultural water and once again the use or emissions.

.png)

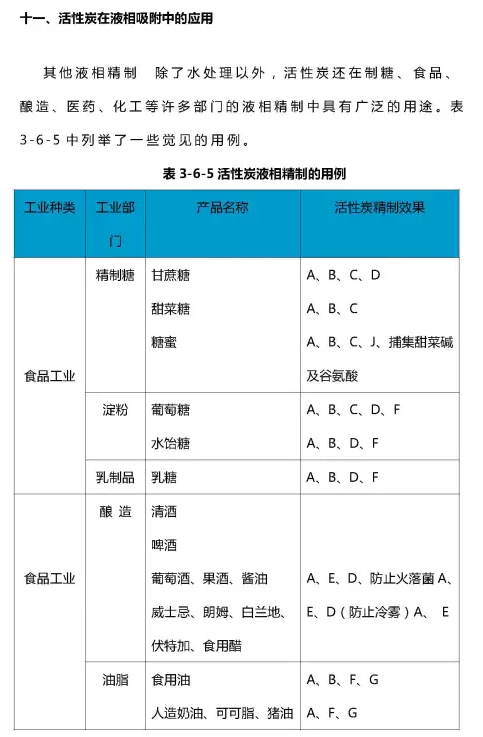

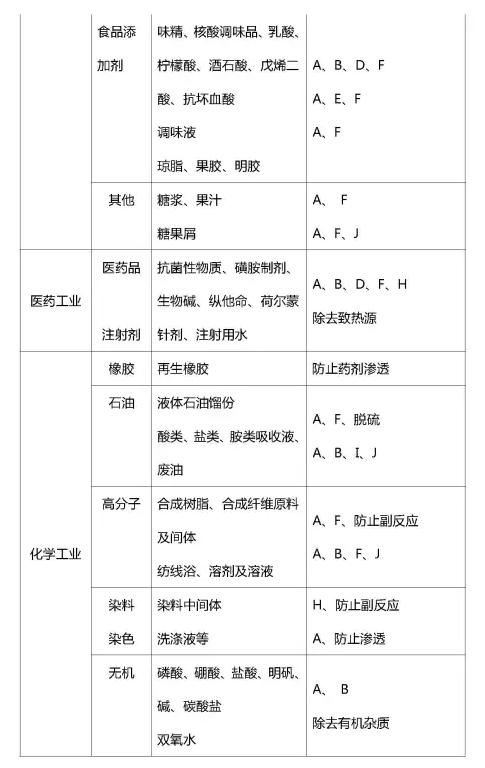

十一、The application of activated carbon in liquid phase adsorption

Other liquid refined in addition to water treatment, many sectors of the activity still carbon sugar, food, brewing, pharmaceutical, chemical and other liquid purification in has a wide range of uses. Table 3-6-5 lists some of the.

Including saturated methane molecule and a small amount of hydrocarbons, set Branch, but with the extension of adsorption time, because of activated carbon with molecular weight of kin compounds adsorption capacity characteristics, adsorption of methane, a lower hydrocarbon gradually by the molecular weight of hexane, amyl alkyl substitution. Results, activated carbon adsorption retention is mainly gasoline components, and small amount of methane, ethane, propane, such as molecular components through the activated carbon la"