With the development of semiconductor, integrated circuit, especially the development of LSI to VLSI (very large scale integrated circuit, circuit linewidth has less than 1um, used in the production process of pure water for more stringent (Table 1), the major indicators of water quality is the resistivity, particles, bacteria and total organic carbon (TOC) requirements.

In the face of such a stringent quality requirements, one of the first to focus on the advanced pure water manufacturing technology and equipment, and combined with strict management, it is very natural, but often overlook the another important factor, that is pure water pipeline design and material selection problem.

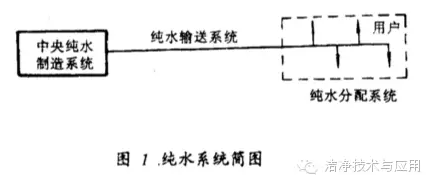

As everyone knows, most of the factories are pure water system including the central water producing system and water transmission and distribution system (Figure 1), that is to say the central water manufacturing system (i.e. water station) to produce qualified water must pass through the water transmission and distribution system of pure water can be sent to the user, and the pure water pipeline pipeline system the length is often hundreds of meters or even kilometers, due to the decentralized distribution line point of use is perplexing, as water professionals not only concern in the central water station to prepare a qualified water, but also concerned about the water transmission and distribution system, and ultimately ensure tens and hundreds of water use requirements.

In this paper, the distribution of pure water pipeline, pipe selection and other issues to talk about some shallow views, in order to cause the attention of this issue.

Pure water piping system design

Water transmission and distribution pipeline system is an important part of the whole system, the pipeline system responsible for the central water station of the high quality of pure water to water as far as possible reduce the input to a point of use, if the pipeline system poorly designed, it will make the quality of water is greatly reduced, even the system calls of Kung Fu payment in full of the branch flows east. Because of the high purity of water, it is very easy to be polluted, the use of the point of dispersion and no law, change the range of large, so that solve the problem to bring a considerable difficulty.

First of all, should be guaranteed within the pipeline pure water flow, namely in the piping system pressure loss is allowed under the condition of flow velocity in the tube to be as big as possible, to prevent bacteria breeding, particle deposition, try to reduce the pipeline dissolution pollution on water quality, pipe flow general according to the following data selection:

Dry pipe flow rate from 1.5 to 3m/s

The branch flow rate of 1 ~ 2m/s

The equipment branch velocity of 0.5 ~ 1m/s

Secondly, in the design of a water pipeline system to solve prevent backwater section (commonly known as "dead water") and "short-circuit" the two big problem.

Solve the two problems of key is correct design of water circulating pipeline system, pure water circulation pipeline different from general branch pipe system, it not only should be pure water pipe and water return tube, in the run, either pure water use how much water can guarantee the pipe in the pure water in the flow state, truly "water does not rot".

In order to ensure the flow rate of pure water pipe and the water return pipe, the water supply of a certain flow rate water system should be composed of two parts:

The water supply of pure water system = design water quantity + circulating water quantity

The circulating water should be 30 to 50% of the design water consumption.

The arrangement method of pure water circulation pipeline is the following:

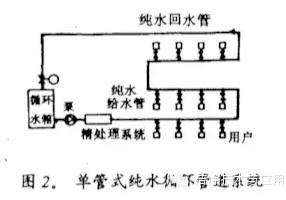

1、single tube (Figure 2)

This is a most simple pure water circulation pipeline system and water pipes with the same diameter or narrow diameter, a return to the fine processing system of the circulating water tank, in order to ensure the working pressure of pipeline system, in front of the access circulation water tank needs is provided with a pressure regulating valve, connected to equipment in the production of pure water pipe should be as short as possible, people think that its length is less than 4 times the pipe diameter, of course, that are often difficult to achieve.

In operation, regardless of whether the user using pure water, circulating pipeline in flow state, obviously in the pipeline system in dry pipe is not "dead" and "short circuit" of.

The disadvantage of this arrangement is:

(1) If regional water supply larger, water is large, resulting in circular pipe is too long, when must ensure than the executive flow, head loss of pipeline larger, thus, the power consumption, the pipeline at the beginning of the end and the end of water supply pressure difference is bigger.

(2) When there is a pipe leakage or pollution, the problem can not be cut open, and must stop the whole system to work in order to overhaul.

Therefore, this arrangement method is limited to a small water area, about 15 to 20 water points, the diameter of the circular pipe should not exceed DN50.

2、Water circulating pipeline system with separate water supply and drinking water return pipe

This arrangement is provided with separate purified water dry pipe and separate backwater dry pipe, from purified water dry pipe connected to the branch in a similar to the single tube through a plurality of water equipment and return to the pure water to dry pipe. The water return pipe is connected with the circulating water tank of the fine processing system at last. Due to this arrangement can have a plurality of circular pipe. The whole system can supply of tens or even hundreds of 100 water water, each cycle branch backwater in the access stem pipe should be installed the pressure regulating valve.

Figure 3 is a water dry pipe and backwater dry pipe layout of reverse flow and its characteristics is water dry pipe's first branch is a return to stem tube end of an access point. Obviously, due to the water dry pipe first branch tube water pressure than the other branch high, reflux distance is short, so it is easy to cause "short circuit". On the contrary other branch will be caused "backwater", obviously this is not an ideal layout.

Solutions should be according to figure 4 arrangement, purified water dry pipe and backwater dry pipe arrangement of flow in the same direction, its characteristics is dry by the water supply pipe is connected with a first pipe and backwater stem tube on the first access tube, followed by water supply branch is connected with the order and return stem tube connected with a time sequence is consistent. Therefore each flow line have experienced roughly the same length, so as to greatly reduce the possibility of "short circuit" and "dead water", so this is an ideal arrangement.

When the multi-storey industrial plant design, due to the top and bottom of the height difference is larger, can produce bottom water pressure is too high, fast return and the formation of bottom "short circuit", the top "stagnant water" phenomenon. At this time should be in each layer of the branch taking additional "flow control valve" (Fig. 5). Flow control valve is characterized by the pressure within a certain range of changes, the flow through the valve basically unchanged. For example: FC production of PLAST-O-MATIC series flow control valve, when the water pressure from 0.1MPa to 0.85MPa between changes in the flow of less than 15%.

Pure water pipe selection

1、The pollution of water quality in pipeline

Pipe selection is very important for the ultra pure water system, the water quality decline due to the pipeline caused by the main source in the following aspects:

(1) for pipe material in the impure substances dissolved in ultra pure water causing water Zhongyang, anion increase, decrease in resistivity and TOC increased.

(2) because of the pipe wall is not smooth and joints, valves and other reasons caused by bacterial retention of the accumulation of breeding and other particles, resulting in the increase of particles in water.

(3) due to the tight control of the pipeline and the valve, the resistivity is decreased, the dissolved gas and the particles are increased.

Therefore, in ultra pure water system should choose low hardenability, smooth inner wall of pipeline and, as far as possible, reduce the uneven joints and fittings. Requires tight connection, strict cleaning and installation process, to grasp the possible pollution of ultra pure water all aspects of water quality.

2、Water pipeline material

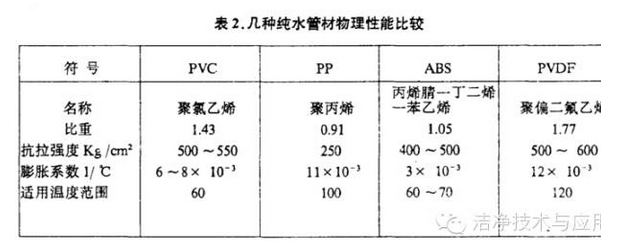

In the ultra pure water system is commonly used in the crime of plastic pipe, such as PVC, PP, ABS and PVDF, of course, there are some occasions, the use of stainless steel pipe.

At present, there is no complete comparison of these materials and reliable test data for the water quality of these pure water pipeline materials. Countries have their own choice of habits. For example, the United States more than PVC tube, the United Kingdom more than the use of ABS pipe, and some European countries are commonly used PP tube, and PVDF pipes are mostly used for water quality requirements are particularly high pure water treatment system.

PVC tube

PVC pipe is the most widely used pipe material in ultra pure water. The commonly used spears, an American firm, SCH80PVC pipeline (SCH80 bit schedule number 80 abbreviated, as the American Standard pipe, pipe wall thickness (high pressure) number said), PVC tube with socket bond, so the tube diameter tolerance requirements more stringent.

polypropylenepipe

There is no PP tube can be used for pure water in China, and many of the imported projects have adopted foreign PP pipe.

ABS tube

ABS tube in pure water system also has a certain scope of use. But the evaluation of it is different, not yet conclusive. At present, the ABS tube is widely used in the water system in China. By the British ALGA company introduced the pure water system using ABS tube, the domestic manufacturers have also produced DN15 ~ ABS DN150 pipes, valves and fittings and thus widely used.

PVDF tube

At present, it is generally believed that the PVDF tube is a material which has stable performance and less pollution to the water quality, which is mainly used in the pipeline of the water fine processing system.

It is reported there is no pollution performance of ultra pure water pipeline material to make a reliable comparison method. This is because the piping material dissolved to the impurity concentration in pure water is too low, making many instruments to be unable to distinguish. There are two ways to do some comparison to pipe materials.

(1) immersion test

This is will a certain area of the piping material after rigorous cleaning immersion in ultra pure water, or ultra pure water into the rigorous cleaning of a certain length of pipeline, after soaked for a certain period of time and determination of various ions and TOC changes before and after soaking, the calculated release amount per unit time per unit area of the pipeline impurities, can do all kinds of pipe is relatively.

(2) the inner wall of the pipeline was observed by electron microscope.

After the pipe is cut off, the inner wall of the material is observed by electron microscope, and the surface of the material is observed by electron microscope. Micro porous deposition of particles and bacteria, observation data show that the PVC pipeline is quite smooth, and the inner wall of the PP pipe has 0.3 ~ 1um of micro holes.